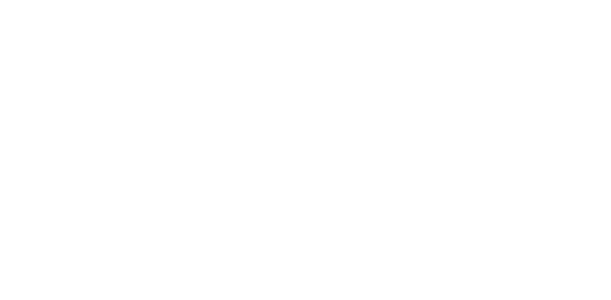

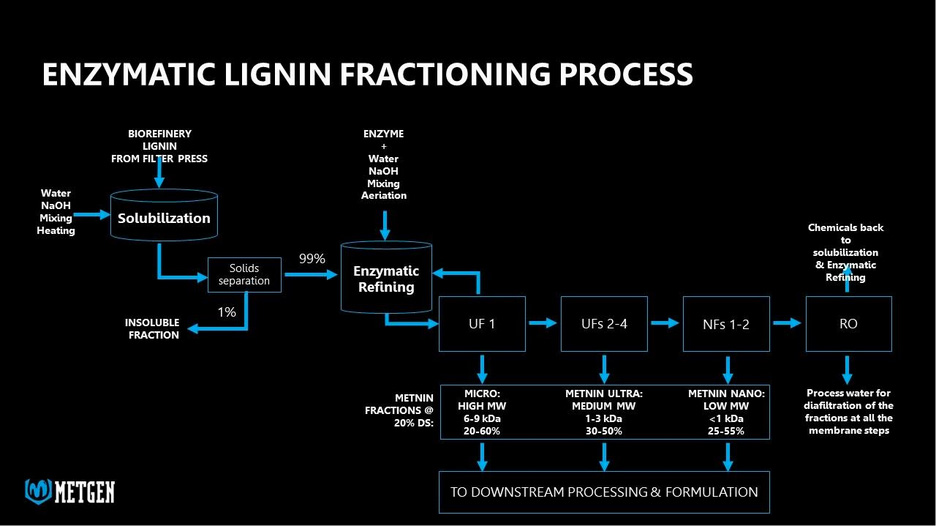

METNIN™ is a process that is enabled by a novel enzyme that not only works but has its optimum at highly alkaline conditions where lignin becomes water-soluble. Never before it has been possible to address lignin enzymatically in such processing conditions.

METNIN™ process solubilizes any kind of lignin and after enzymatic refining fractionates the material according to a very specific molecular weight. Additionally, these fractions are easily tailored to have end-user specific chemical characteristics, including, solubility, dispersity, viscosity (liquids), particle size (powders), Tg, polarity, number of various surface-active groups, pH, ash content, etc.

The process – thanks to the selected alkaline conditions – utilizes widely available industrial standard membrane systems. The operations are robust and fluent and allow for recycling of water and sodium hydroxide in the process, almost eliminating the waste.

METNIN™ is an epitome of MetGen’s biotech competence: based on a new-to-the-world enzyme complemented by process technology and connected with adjacent chemical processes.

What is more, through the vast collaboration network, MetGen has already connected with more than 100 companies willing to productize the lignin in a multitude of applications. We have connected the supply of lignin with the chemical and material companies in need of high-value substitutes for oil-based chemistries. Valorizing lignin really has quite an impact on the techno-economic performance of any biorefinery.

To accelerate the productization of METNIN™, we have launched a webshop for samples.

With the full basic engineering package, MetGen is ready to license out this technology to be implemented at your biorefinery as well. Please find out more about our presentations and webinars.

We are always here for you if you have any questions. Please find your contact here.

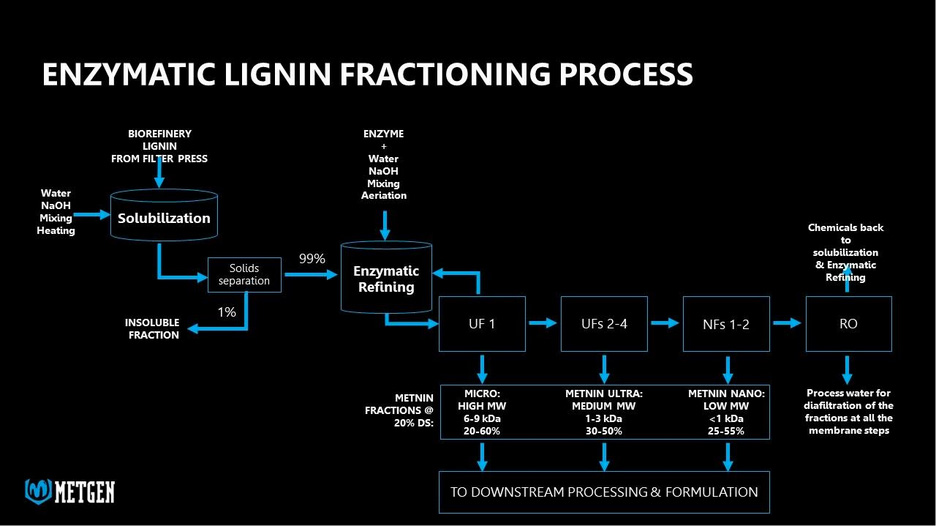

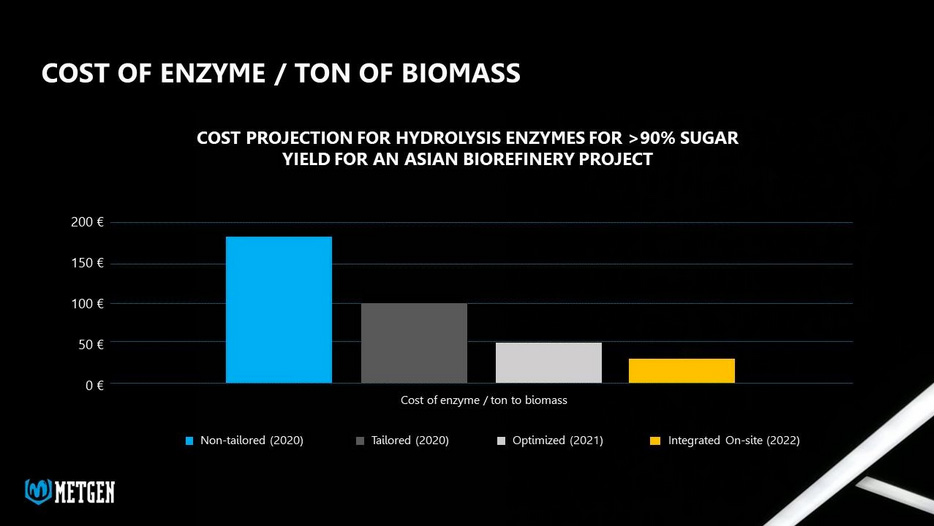

Biomass comes in many forms. Affordable processing requires us to fractionate the biomass to its basic components as thoroughly as possible with the lowest cost. With this in mind, the material in the process is always a unique combination of feedstock and pretreatment. Therefore, the enzymes must be tailored for the task as well.

Biomass is not oil – it’s the soup of the day

MetGen has the competence of creating a blend of enzymes that is optimal to your biomass. Additionally, genetically engineering the selected enzymes further optimizes the performance on your feedstock. Once the enzymes are fine-tuned we can provide a customer-specific production system for hydrolysing your specific substrate with the highest yields, least amount of enzyme, and lowest cost.

MetGen is also working on next-generation technologies making the hydrolysis process continuous and providing enzymes multiple cycles in the process. This new approach holds a potential to enable very utilization of tough but low-cost feedstocks with a fraction of the enzyme cost. Stay tuned for more.

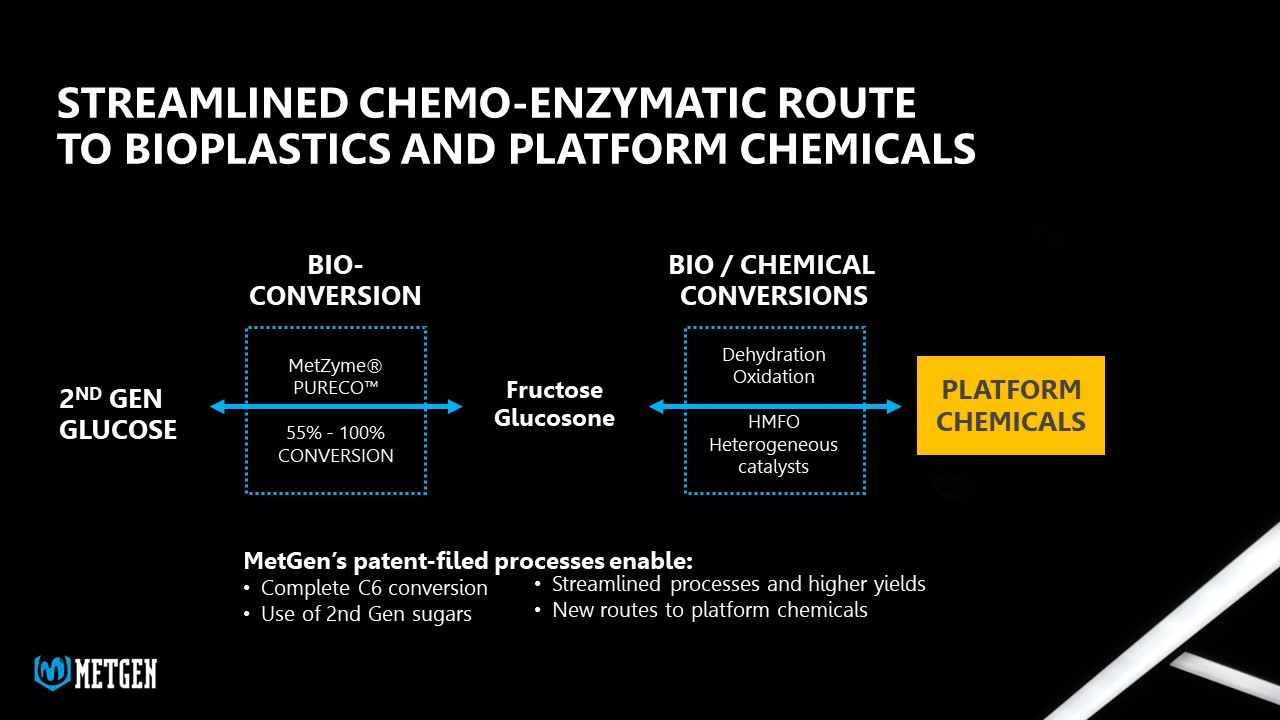

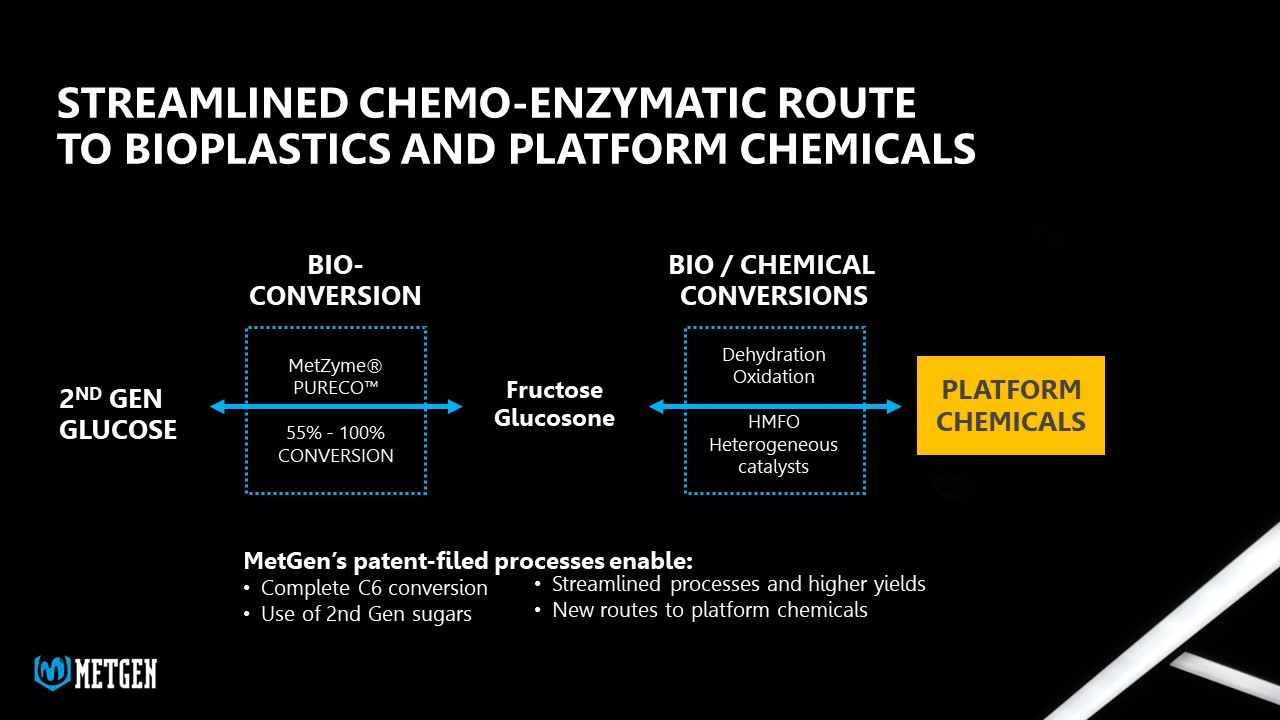

The sugar fractions especially glucose and xylose can be also converted to value-added molecules.

MetGen has for example enabled the bioconversion of unpurified lignocellulosic sugars (or pure glucose in that manner) to glucosone and fructose. These intermediate sugars are important steps along the way to 5-HMF and FDCA, an important platform polymer for multiple applications in plastics.

MetGen is looking forward to expanding PURECO™ solution portfolio together with industrial partners.

The next item in the pipeline includes conversion of 5-HMF to FDCA in a single enzymatic reaction and a process for creating long-chained hemicellulose.

Our ENZINE® Technology platform provides the perfect tools for the co-creation of new enzymes and bioprocesses. While we’re already looking into capturing CO2 into bio cement and plastic degradation and infinite recycling, perhaps you have a new opportunity in mind. We have the tools to materialize the biotech solutions for your challenges.